Ultrasonic Hydrogen Gas Meters

We are conducting research on hydrogen gas meters in preparation for the coming hydrogen society.

Given that it does not emit carbon emissions, hydrogen is garnering attention as a clean energy resource in order to achieve carbon neutrality, an ambition of the sustainable development goals (SDGs).

Hydrogen is an important fuel to meet heating energy demands. It is also an extremely important gas used as a raw material for producing ammonia and e-methane (synthetic methane), which are expected to be used as alternative fuels for coal-fired power plants and utility gas.

Hydrogen fuel cell vehicles (FCVs) and hydrogen stations are gradually becoming more common in urban areas, and pure hydrogen fuel cells using pipeline-supplied hydrogen are being commercialized.

We provide ultrasonic hydrogen gas meters that achieve high flow measurement accuracy and long battery life in order to ensure fair pricing for hydrogen.

High flow measurement accuracy

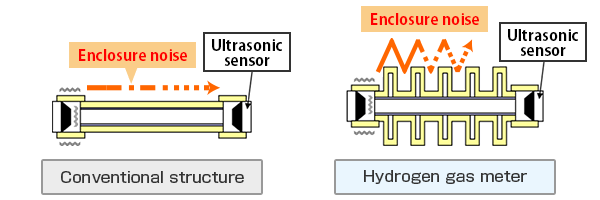

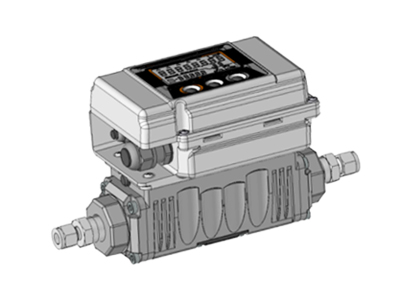

Hydrogen is one of the gases through which ultrasound is least likely to propagate. As a result, the ultrasonic waves that propagate through the housing (housing noise) become relatively large compared to the ultrasonic signals that propagate through the hydrogen gas, reducing the flow measurement accuracy. We have therefore adopted a unique housing shape (patented), shown in the figure, to reduce housing noise and realize highly accurate flow measurement.

10 years of continuous operation on battery power

By employing the following two patented low-consumption ultrasonic measurement technologies, we have created an ultrasonic hydrogen gas meter that can operate continuously for 10 years on battery power alone, just like a regular gas meter.

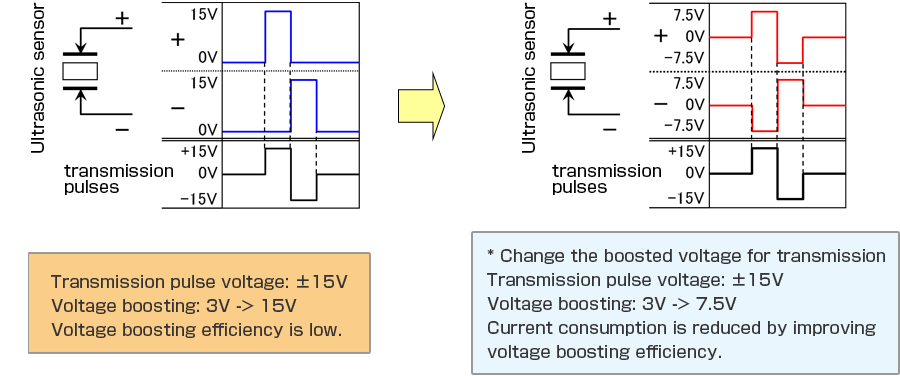

■ Transmission of ultrasonic signals with reduced current consumption

By devising a method of applying voltage to the ultrasonic sensor, we reduced the amount of power consumed during the transmission of ultrasonic waves.

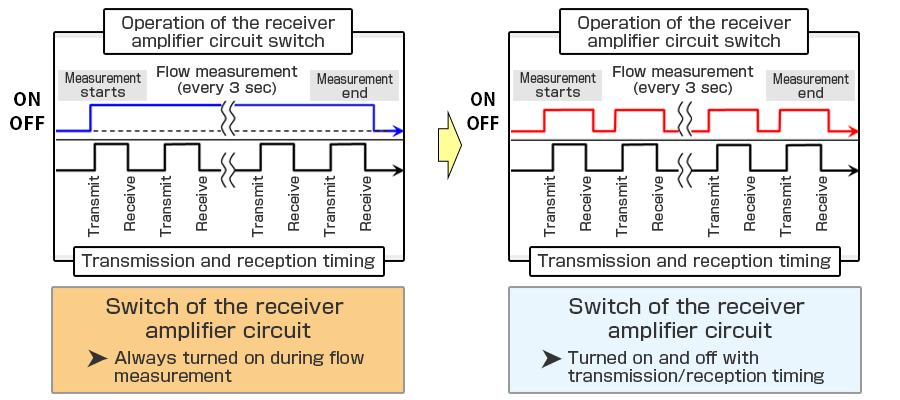

■ Minimizing the operating time of the circuit

By controlling the operating time of the ultrasonic transmission circuit more precisely than before, we reduced the amount of power consumed during flow measurement.

Researcher's voice

■ What other issues and discoveries did you come up with during your research on hydrogen gas meters?

When we first started this project, there was an overwhelming lack of information about measuring hydrogen using ultrasound, and even when we conducted tests, we were met with a series of unexpected results. For example, we were predicting that we could measure air without any problems, but that we would get 1/4 of the signal strength for hydrogen, but the moment we measured hydrogen, the ultrasonic signal disappeared. . It turned out that the cause of this was a slight gap in a certain part of the flow path, but this gap was at a level that was not a problem at all according to textbooks and literature on acoustics. In this way, even if we apply theoretical values obtained from textbooks and literature, we have had many difficulties in finding that things do not actually work out as expected. Conversely, with a normal gas meter, the ultrasonic signal becomes smaller as the flow rate increases (flow rate dependence of the ultrasonic signal), but it was also found that when measuring with hydrogen, the signal strength hardly depends on the flow rate. In fact, there were some parts that were easier to design.

■ What kind of response or solution did you take from there?

It was discovered that the gap was the cause of the ultrasound not transmitting properly, as the signal strength recovered when the gap was filled in for another test. With such a lack of information, I was acutely aware that all kinds of data and their analysis results, while interrelated, can provide hints for solving various problems.

■ What further improvements are being made, and what future improvements do you envision?

Currently, we are collecting data on actual operations through demonstration tests of pure hydrogen fuel cells, which are operated by installing ultrasonic hydrogen gas meters and supplying hydrogen through a pipeline. We are also planning to introduce other ultrasonic hydrogen gas meters. By combining the data obtained from these meters with the gas meter technologies we have developed, we will develop new ultrasonic hydrogen gas meters for the hydrogen-based society of the future. We hope to make proposals.

Related information

As part of the Hydrogen on-pillar Pipeline Demonstration Project to Promote the Use of Hydrogen Energy (adopted by the Ministry of Economy, Trade and Industry) underway in the town of Namie, Fukushima Prefecture, our ultrasonic hydrogen gas meters were installed under the supervision of Brother Industries, Ltd. A demonstration experiment was conducted from October 2021 to February 2022. The measurement data collected in the hydrogen supply environment, close to that of actual operation conditions, will be used to confirm the results of the demonstration experiment and identify issues. The data will also contribute to the study of safety functions and the construction of billing systems as we work to help realize a hydrogen-based society.

|Related links|

> Brother Industries, Ltd.|Japan’s First Hydrogen On-Pillar Pipeline Demonstration Project Undertaken by a Public-Private-Academic Team

> Brother Industries, Ltd.|Transportation Demonstration Experiment Using a On-Pillar Pipeline to Promote Hydrogen Energy

With the cooperation of Iwatani Corporation and the city of Kitakyushu, we have installed ultrasonic hydrogen gas meters in Kitakyushu Hydrogen Town and are conducting a demonstration experiment there.

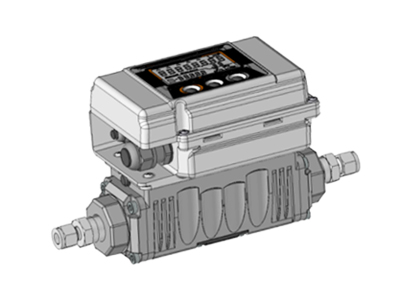

These ultrasonic hydrogen gas meters have been updated based on the knowledge gained through our previous model, which achieved stable hydrogen flow measurements. In consideration of safety for practical use, a mechanism to shut off hydrogen in case of a disaster or other issues and a sensor to detect earthquakes were included in the system package.

In the Regional Collaboration and Low-Carbon Hydrogen Technology Demonstration Project (commissioned by the Ministry of the Environment) in the city of Shunan, Yamaguchi Prefecture, we installed our ultrasonic hydrogen gas meters and have been collecting data through actual operations since June 2016 with the cooperation of Iwatani Corporation, a participant in the demonstration project.

In Shunan, we are conducting a demonstration experiment by installing ultrasonic hydrogen gas meters in an outdoor piping/outdoor installation environment for the first time.

After collecting measurement data for approximately five years, we have confirmed that the meters can perform stable measurements in the same harsh conditions of direct sunlight as conventional gas meters.

Inquiries about research and development of the latest technologies

Aichi Tokei Denki Co.,Ltd.

Please contact us using the General Inquiry Form.